There are three types of ways used to join pieces of metal, they are brazing, soldering, and welding.

Filling gaps in some metal parts special techniques are used but these three types of techniques are for a different purpose.

Also, it depends on the material and application used.

Welding

Such as aircraft fuselage or a car body, welding is to create a very strong bond between two pieces of metal, that you can withstand all kinds of stresses and strains.

- First of all, the metals must be similar, for example, you can’t weld steel to copper.

- The temperature must be high so that you can weld two metals and join them together.

- In welding, you can also use filler metals in order to seal the gaps.

- When the welding job is done, the weld will be strong as the surrounding “un-welded” metal. However, if too much heat is used you could change the metal’s characteristics and weaken it instead.

- Depending on what metal you work on there is various welding techniques. That’s why during a welding program, you can learn which techniques to use. Ultrasonic, lasers, electrodes, or oxyacetylene gas provide different welding results and they all have different heat sources.

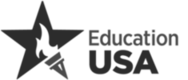

Soldering

Similar to welding is soldering but it is for a very different purpose.

It’s used for softer materials like reels and tubes.

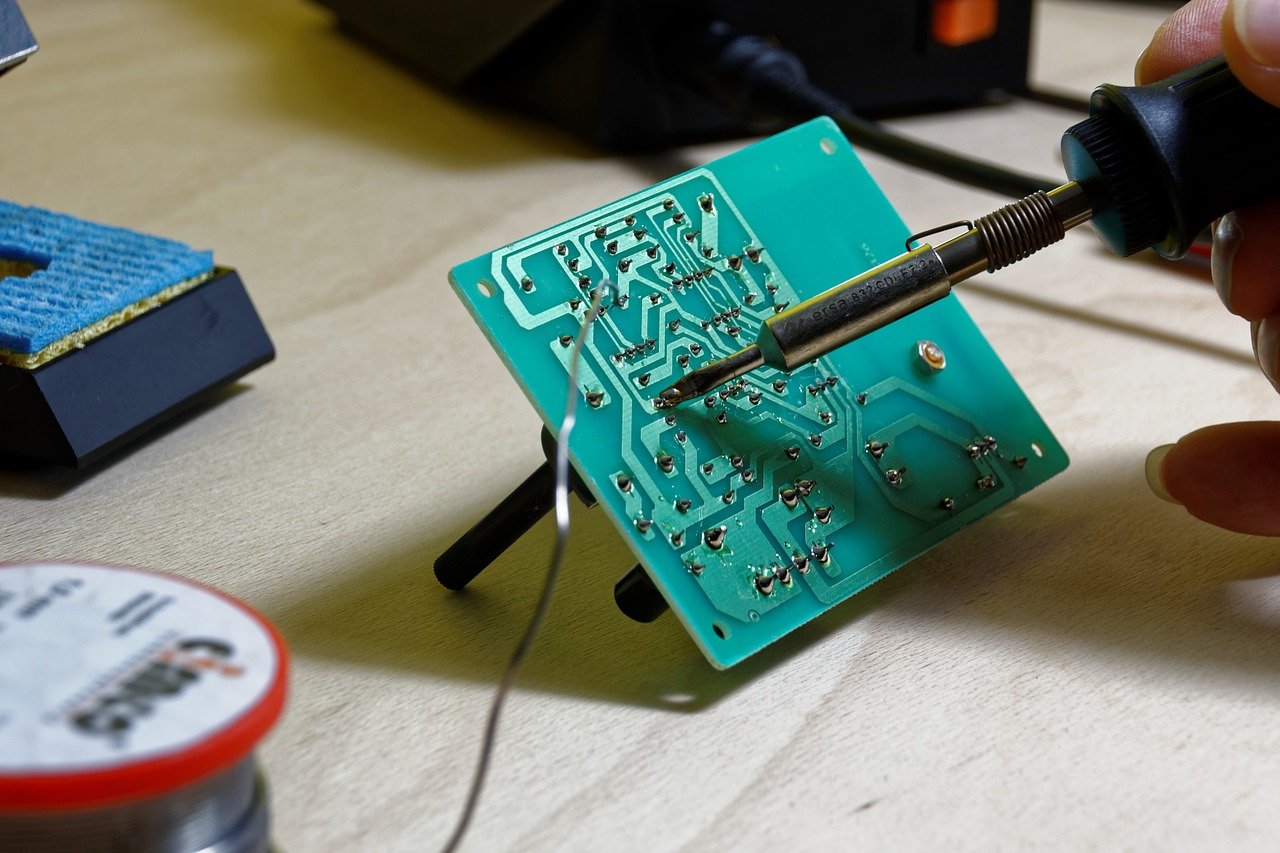

It’s actually mostly used in electronic devices because it helps with connecting the components electronically.

- Compared to welding, soldering uses a low temperature to join metals

- Filler are used that should be melted at below as 650 F

- Iron, brass, silver, and gold are the metals that can be soldered. The bond happens once the melted soldered material becomes solid.

- Because it’s not a type of mechanical connection like welding or brazing. These are stronger than soldering. But if soldered wasn’t applied properly the electricity won’t conduct the metal pieces.

- In this case Welding and brazing flux might be used to clean metal surfaces. This is done over the pieces of solder so that they can be joined with a flow.

Brazing

Brazing is very similar to welding but here are key differences and why it’s used for different purposes.

- Brazing is about heating and melting a filler alloy and the metal pieces are joined when one of the fillers becomes solid.

- In this case, the allowed filler must be at a lower temperature than the metal piece.

- For joining different metals brazing allows aluminum, silver, copper, gold, and nickel.

- The metal parts of wetting promote liquid flux material, they can be joined more easily because the filler flows easily over them.

- Brazing joins stronger pieces, compared to welding.

Welding vs. Soldering

By the American Welding Society (AWS) soldering is classified as a liquid-solid phase bonding process.

It’s classified by that the filler metal, once meted becomes liquid, while other materials stay solid.

Unlike welding’s workpieces, soldering is not about melting.

Here the heat source is different.

As mentioned before, soldering takes place when the temperature is lower than 650F while for welding 10.000F is used and can reach 50.000F.

Brazing vs. Soldering

The difference between soldering and brazing is the temperature at which the process is done.

Brazing is done at a temperature of 840 F and soldering takes place at a temperature of 650 F.

Let’s Sum Up the Brazing and Soldering Advantages

- Low temperature.

- Temporarily joined or permanently.

- Dissimilar materials.

- Speed of joining.

- Damaging parts of less chance.

- Cooling and slow rate of heating.

- Varying thicknesses of parts can be joined.

- Easy realignment

Brazing and soldering can be easily overlooked when it comes to joining processes.

But they can be great for starting a small business because it requires less investment compared to welding.

It’s great for homes, farms, and shops, and gives amazing results.

Brazing, soldering, and welding are used for different jobs and in different sectors.

For all of them, it’s better to have the training and a certificate before applying for a job.

But before you start training consider the factors and the benefits each type of technique brings.